From the Banks of the Mighty Mississippi to the Rest of America

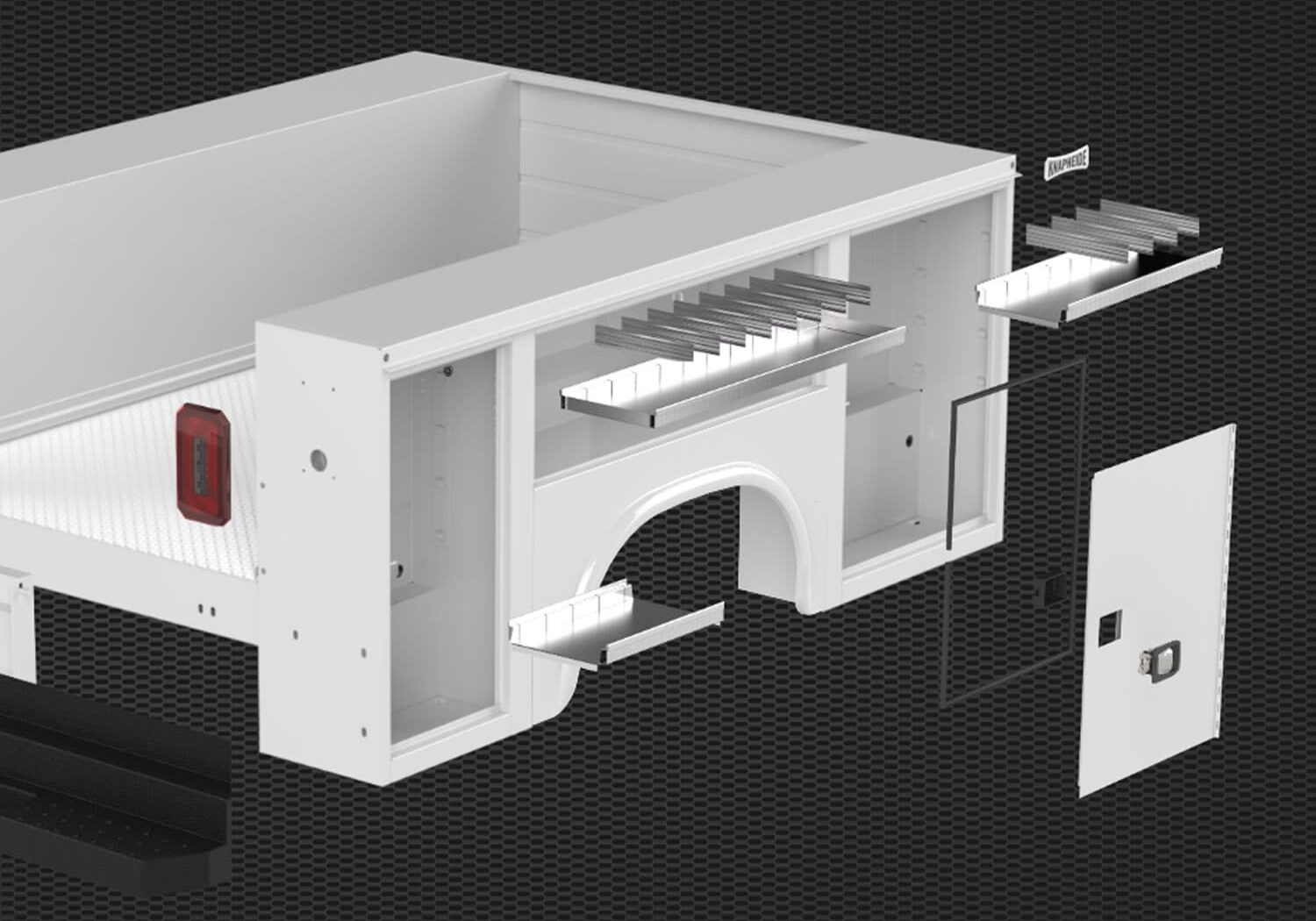

From building wagons in the 1800s to bodies for the emerging automobile market in the early 1900s, we forged our reputation as a high-quality manufacturing company throughout the 20th century to present day.

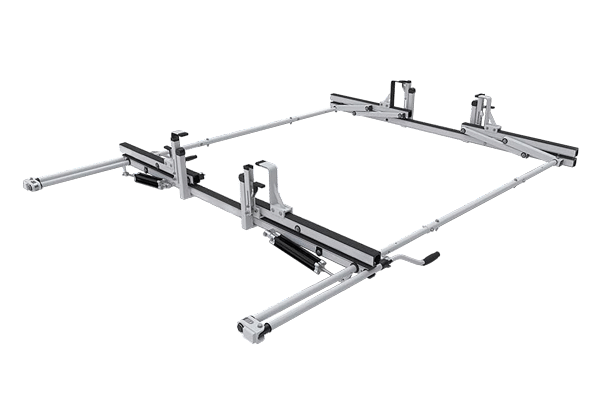

Today, in addition to still producing the highest quality truck bodies and van equipment, we're the leader in commercial vehicle equipment upfitting and installation for any need.

Our continued commitment to innovation and customer satisfaction helps us deliver reliable and innovative vehicle upfits tailored to the needs of businesses across various sectors, solidifying our reputation as a trusted partner in the commercial vehicle market.

2500+ Employees

30+ Knapheide Stores

250+ Upfit Partners

The Top Equipment Suppliers

Our History Pushes Us Forward

Six generations of leadership, perseverance and growth.