Publish Date

June 15, 2019

Social Share

With the size and scope of equipment on jobsite growing larger and more expansive, it’s nearly impossible to transport equipment back to the shop for regular maintenance or repair. That’s why the workstations on wheels known as mechanics trucks are a solution for a variety of industries in need of on-site maintenance for their large equipment.

Mechanics trucks offer nearly limitless capabilities as far as field maintenance. They can be nearly as complex as the equipment they service, therefore properly spec’ing a mechanics truck is no simple task. Bruce Bunting, mechanics truck specialist at The Knapheide Manufacturing Company, has seen a lot of mechanics trucks throughout his career.

“These trucks can be a huge tool for a company’s return on investment. But if they’re over spec’d or under spec’d, there will be ROI left on the table at the end of the day,” Bunting said. “If you over spec a truck and you have more capacity than the mechanic needs and more cost to get back before seeing revenue from mobile service. Meanwhile, under spec’ing a truck gives you a mechanic that can’t get the job done properly, which leads to productivity loss and is an accident waiting to happen. Putting together the right mechanics truck requires a solid understanding of the everyday application of that truck.”

That’s no easy task, but no worries. We’re here to help. Consider some of the following tips before making your next mechanics truck purchase.

Crane

A mechanics truck isn’t a mechanics truck without a crane, regardless of crane size or type (electric or hydraulic). Typically, spec’ing the crane is the best place to start on your body. Most other things like body and chassis size will fall in line.

A few important questions Bunting stresses during the crane selection process are, “how much weight will you be lifting, at what distance and how often?” Knowing the weight and distance are obviously important, but frequency of use has a lot to do with the type of crane to use; electric or hydraulic. If loads and usage are relatively light, a customer may be able to opt for a more cost effective electric crane. A hydraulic crane will be more necessary if a user frequently turns to the crane to assist with heavier loads (over 6,000 lb. maximum capacity).

A wide range of telescopic cranes are available from many different crane manufacturers. Boom lengths can range from five feet up to over thirty feet with maximum lift capacities stretching from 900 to 14,000 pounds.

“If you fully understand the crane applications, it will make spec’ing the rest of the truck that much easier,” Bunting said.

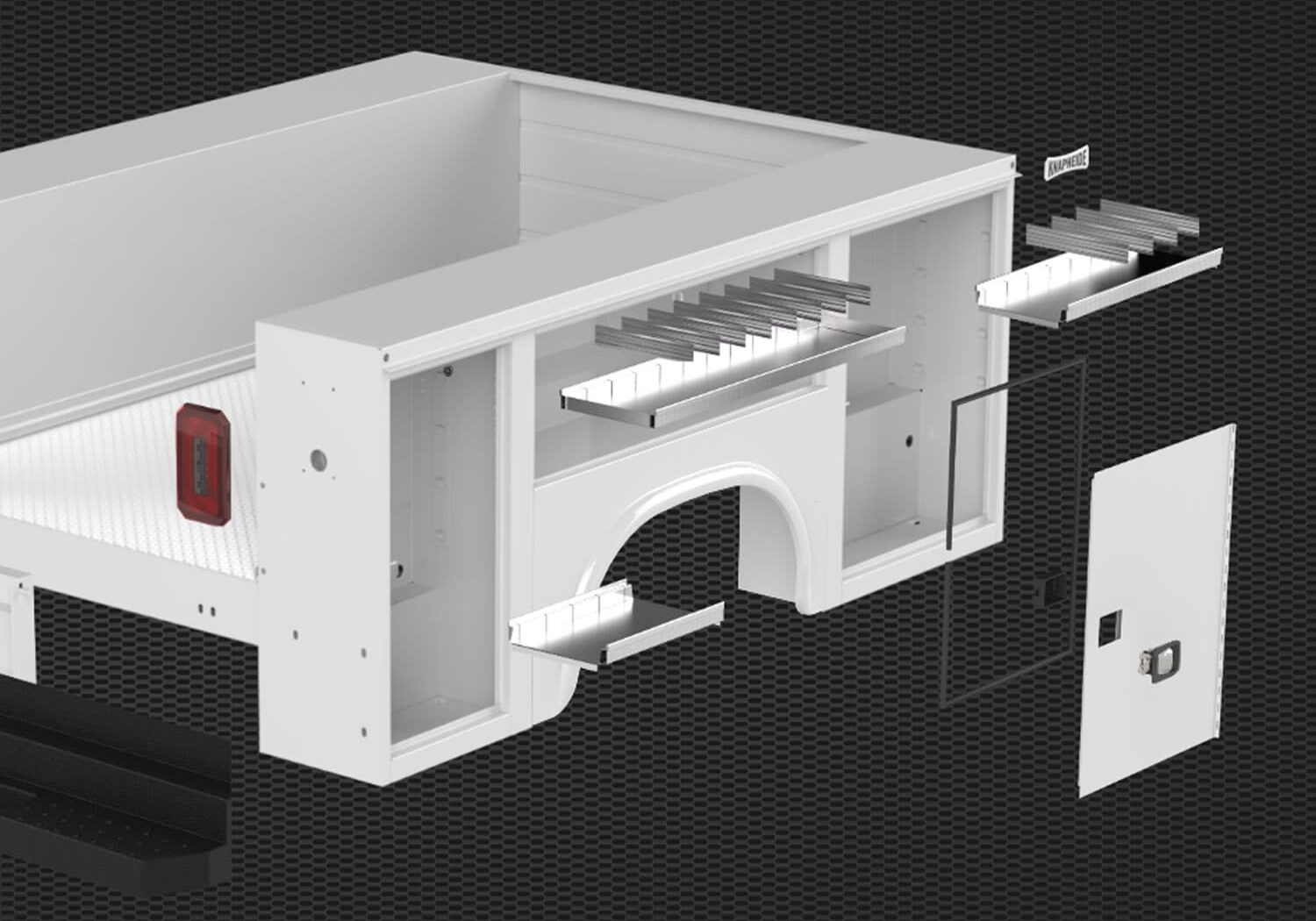

Body

While the crane is the most visible tool on a mechanics truck, it’s certainly not the only one. Mechanics carry a wide variety of hand and power tools to get the job done, so storage space is premium.

“Mechanics are out in the field and they rely on the tools and parts on their truck to get the job done. Some mechanics are completely isolated, so there’s no quick drive back to the shop to get what they need,” Bunting said. “If they don’t have it on their truck, they can’t complete the job. So cutting them short on storage space is not a wise decision if you want to maximize their productivity.”

In addition to keeping user’s storage requirements in mind, the size of the body must also match the application of their crane

“A hydraulic crane with a maximum lift capacity of twelve thousand pounds will not fit (or certify) on a nine foot body,” Bunting said. “Cranes put a tremendous amount of torsional stress on a body, so the body needs to match up to the size of the crane to maximize the life of the investment.”

Properly built crane bodies require a reinforced understructure and crane compartment to withstand the lifting forces of the crane. There are many sizes of crane bodies to choose from, ranging in lengths from eight feet to more than 17 feet.

“A body is a rolling billboard enabling the user to advertise their company wherever they go. Be sure the body you choose has quality prime (E-coat) and finish paint so your body looks just as good as the cab five years down the road,” Bunting said.

Chassis

By the time you choose the crane and body, the chassis selection process should be pretty narrowed down.

“You now have a crane, body, and chassis that all have to work in concert with each other, as the chassis is dependent upon your crane and body selection,” Bunting said. “There are numerous factors when selecting a chassis that you need to be cognizant of including the GVWR (gross vehicle weight rating), RBM (truck frame resistance to bending), CA (cab to axle measurement), engine type, PTO, transmission, drivetrain, along with creature comfort options for the mechanic.”

A 12,000 pound crane on a 14 foot body won’t work on a Class 5 chassis because there needs to be enough GVWR available for the crane and body, in additions to all the tools, equipment and parts a mechanic needs to store on a truck.

“Many companies want chassis that are under the 26,000 GVWR threshold so their mechanics aren’t required to obtain CDLs,” Bunting said. “It’s not always possible as many mechanics haul a significant amount of weight in tools and equipment, especially those who cover areas far away from the shop.”

Choosing a chassis with an adequate RBM rating will ensure the frame rails will withstand the forces applied throughout the lifecycle of the mechanics truck. Chassis manufacturers publish these numbers and responsible upfitters factor in RBM before starting an upfit.

The cab to axle measurement will be directly tied to the body length selected. For example, if your mechanics truck requires an eleven foot body you will need to select a chassis with an 84 inch CA.

There are numerous other application questions to be answered about your chassis. Will your truck be idling quite a bit? Is there a chance your end users might not be familiar with a manual transmission? Will your truck be going off road? All of these questions determine engine type, transmission and drivetrain.

“These questions associated with the chassis need to be asked as they are just as important as spec’ing the right crane and body for the mechanic,” Bunting said. “Other factors to consider are size and placement of the fuel and DEF tanks along with the location of the exhaust, all of which can interfere with the upfit if not ordered correctly from the manufacturer.”

COMPRESSOR/WELDER/GENERATOR

Compressors, welders, and generators are all common pieces of equipment found on mechanics trucks. These tools enable the mechanic to run pneumatic tools, perform welds in the field, and provide power without idling the truck engine.

Compressors are typically mounted on the top side of the body opposite to the crane with a roller fairlead located at the rear of the body for easy and quick access.

“You see mostly rotary screw compressors in the industry, as these are relatively small yet are designed to run for a long period of time, while reciprocating compressors are intended for shorter uses. Most of the time, a half inch line is sufficient to power the mechanics power tools, however there are times when a larger hose reel line is required to power the bigger pneumatic tools,” Bunting said. “Ensure you select a compressor with enough CFM (cubic feet per minute) for the tool or tools you need to run.”

If the service or repair application calls for a welder, there are several factors to consider. What type of metal is being repaired? Will it be diesel or gas powered? What is the required weld output?

Increasing in popularity are the ‘all-in-one’ systems that combine the functionality of a compressor, generator, and welder into one unit. These all-in-one systems save on overall space and since they provide their own power it enables the mechanic to eliminate idling the truck engine as a power source. Utilizing an all-in-one system can also reduce the overall vehicle weight.

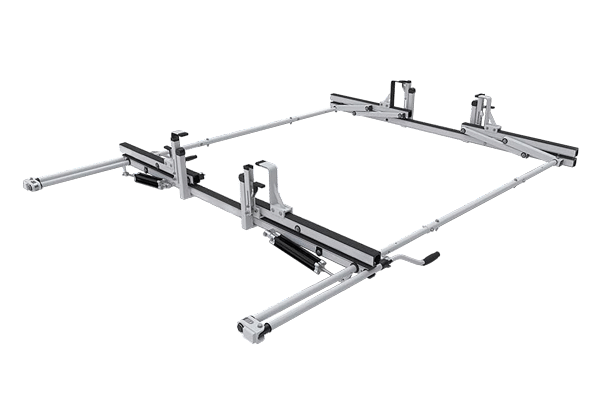

Accessories

Properly spec out the mechanics truck with the appropriate accessories and the productivity benefits will pay dividends.

“One of the most overlooked aspects of mechanics trucks is organization and how superior organization leads to greater productivity and efficiency on the jobsite,” Bunting said. “Ensuring the mechanics drawers meet the application requirements is very important. There needs to be enough drawer space for all the hand and power tools so everything has a dedicated space, easy to find and retrieve.”

Mechanics drawers come in a variety of sizes and configurations as well as different material construction, most commonly steel or aluminum. Understand how much weight will be carried in each drawer and how severe the jobsite environments will be to ensure you spec the right mechanics drawers for the application.

Lighting, both external and internal, makes a huge difference on the jobsite if spec’d properly. Most mechanics will receive calls during the late hours of the night or wee hours of the morning to get out and service downed equipment, which means they work in low light conditions. Having interior compartment lighting so they can find the tools they need and auxiliary external lighting so they can safely operate the crane can be vital not only to their productivity but to their safety.

All throughout North America there are mechanics trucks going to work, from urban to rural areas. Some mechanics are challenged with working in high crime and theft areas.

“We’ve seen numerous mechanics that prefer to keep everything that is in the cargo area out of sight. If it can’t be seen there is less of a chance it will be stolen,” Bunting said. Consider utilizing a lockable telescopic sliding roof or custom tarp cover for the cargo area.

These days, mechanics pull double duty and are performing both equipment repair and preventative maintenance out in the field. Mechanics are tasked with fluid replacement, from coolant to oil. Lube skids, with dedicated storage for both new and salvage fluids, enable a mechanic to easily retrieve salvage fluids and dispense new fluids.

“If you spec a mechanics truck to fit the application it will be a huge productivity and safety tool that provides years of return on your investment,” Bunting said. “Improperly spec a mechanics truck and prepare for workers compensation claims, lost productivity and frustration with mobile service. Always form the best understanding of the application to help guide specification decisions for your next mechanics truck.”

“Lastly, ensure you select an upfitter with a great deal of experience in installing and servicing mechanics trucks. These trucks are a big capital investment, so quality installation and after-sale service is important in keeping your mobile service running at full potential.”