Publish Date

June 15, 2019

Social Share

Dump bodies are utilized in many different industries, from hauling aggregate in mining applications to transporting grass clippings in lawn care applications. Dump bodies have eliminated the back breaking work of unloading bulk materials off of the truck, greatly improving efficiency and safety on jobsites around the world.

Light duty dump bodies are commonly utilized in construction, snow removal, lawn care, municipalities, landscaping and many other applications. Most light duty dumps are compatible with class three, four, and five chassis (one ton and larger). Properly spec’ing your next light duty dump is important to ensure maximum productivity and safety for the operator. Check out these steps to get you started with the spec’ing process.

Understand Load Weights

“Many operators understand the load limits of their truck and how much payload is available, but the problem is many of them aren’t accurately calculating the weight of what they haul,” Greg Sunila, Regional Sales Manager with The Knapheide Manufacturing Company said. “Hauling more than your body was designed to hold or more weight than your chassis has available in payload will cause unnecessary wear and tear on the truck which can eventually lead to a breakdown.”

What You’re Hauling: Understanding what materials will be hauled (sand, gravel, mulch) and how much (in cubic yards) will help determine your load requirements for your next dump body. “Two characteristics can greatly affect the bulk material weight, moisture level and compaction, so operators need to keep this in mind when calculating the weight of the load.”

Volume and Weight: Light duty dump bodies typically have a volume capacity rating ranging from two yards up to four yards, depending upon the body length and side wall height, along with the available payload and hoist rating. “The more weight you will haul, the more likely you will need to select a class five chassis. If you are hauling relatively light materials such as compost or mulch, a class three chassis will probably be sufficient,” Sunila said.

Hoist: Available hoist types include either electric or PTO powered. Electric hoists are powered by the battery and therefore don’t require the engine to run to power up or down the dump body. PTO powered hoists require the engine to be running for hoist up or hoist down operation. Each hoist type has its’ benefits, lighter duty applications are typically better suited with an electric hoist, while the PTO powered hoist is best fit for heavier duty cycles.

Choosing the Right Chassis Specifications

Chassis selection entails much more than just choosing which chassis class you’ll need. Careful consideration needs to be taken when selecting the engine and drivetrain. If your truck will be idling frequently and performing numerous dump cycles, a diesel engine would be the best application. If your application will require less idle engine time, a gas engine may be the way to go.

“Unfortunately dump trucks don’t stay on a nice concrete or paved surface throughout the day, they are required to venture off road on a jobsite to dump and deliver. Most of the time a four wheel drive chassis is required for the application,” Sunila said.

Ensure the cab to axle measurement of the chassis you select is compatible with the dump body length, for instance a nine foot dump body will require a cab to axle measurement of sixty inches, while an eleven foot body will require an eighty-four inch cab to axle.

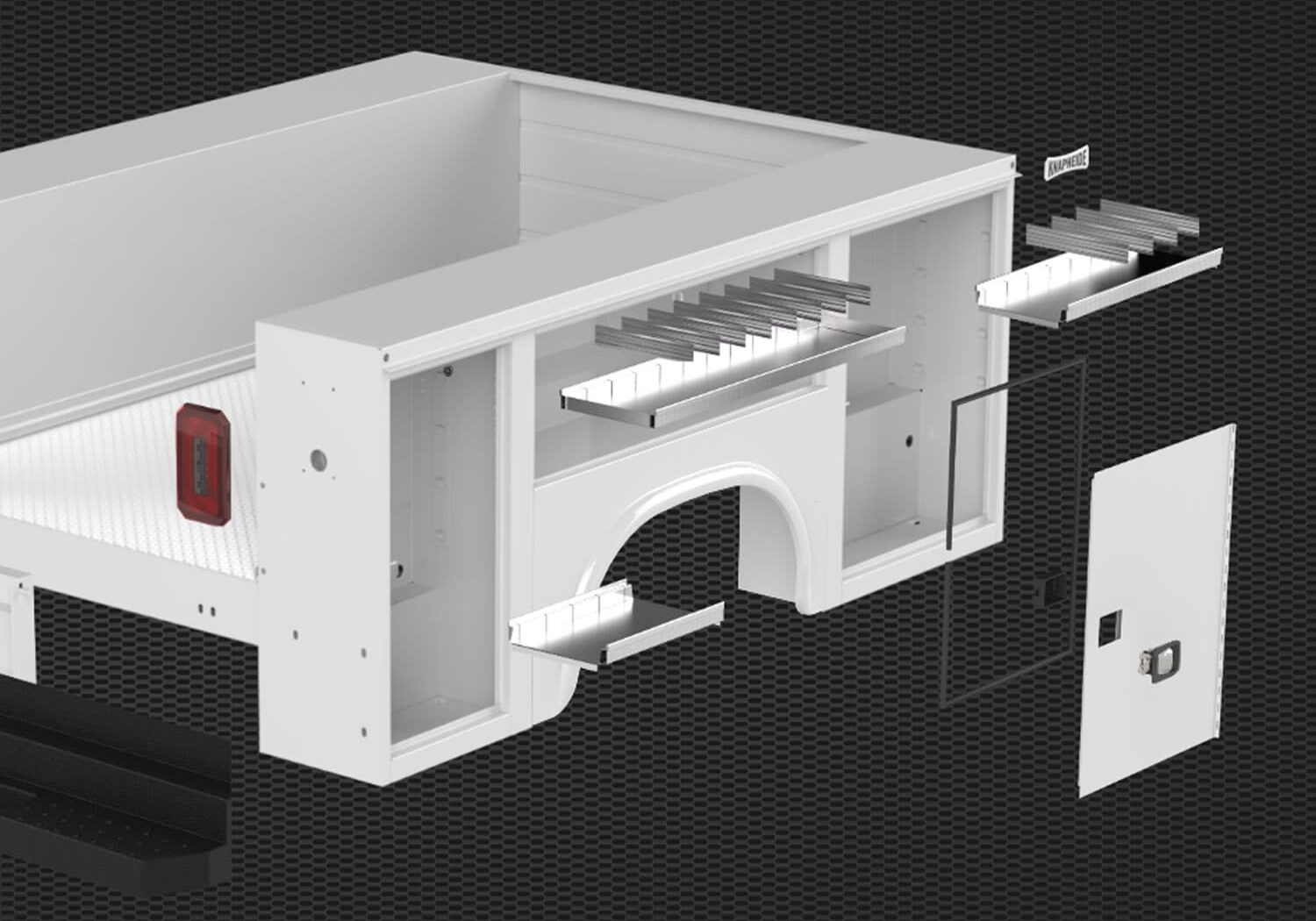

Customize the Body to Your Needs

There are many available options and accessories to further customize your next dump body to best fit your needs.

Body Structure: One of the main variances from application to application is the understructure of the body. The two main options are “western style,” which lacks crossmembers and features fully-boxed long sills, and a standard body containing crossmembers in which the long sills are interlaced with or stacked on top of. “Many times it is a regional preference. Certain regions prefer one type over the other. The western style has gained popularity over time in the snow belt regions, due to the lack of crossmembers the understructure easily sheds snow, chemicals, and road debris, which helps prevent corrosion.”

Cab Guards: A cab guard is required on dump bodies and protects the cab from bulk materials during transit. A quarter cab protector covers a small portion (around 1/4) of the top of the cab, while a full cab protector provides (you guessed it) a full shield on top of the cab. You can typically save 100 pounds of payload or more with a lighter-weight quarter cab guard, at the expense of coverage and storage. If the operator needs additional storage for oversized items, full cab protectors provide additional real estate. “With many landscaping applications, the operator needs a designated place to store a wheelbarrow, which a full cab protector accommodates,” Sunila said.

Storage Options: Since dump bodies offer zero storage beyond what can fit in the cab, additional storage options are usually popular. Underbody toolboxes, mounted directly to the chassis frame, and storage packs, mounted between the body and cab, are both great options to create more body storage.

Body Sides: Operators can choose from drop or fixed side dump body models. Drop side models feature hinged sides that drop down 180 degrees for easier material loading. Fixed side models are more structurally sound for heavier duty applications and require no maintenance since there are no moving parts. If the operator desires taller sides on the dump body, a sideboard extension can easily be added to both sides.

Other Accessories: Certain applications, such as construction or lawn care, require a light duty dump body to haul a trailer with a receiver or pintle hitch. If there are no trailering requirements, the dump body must be equipped with an ICC bumper for underride protection according to FMVSS regulations. Many states have regulations that prohibit spillage of any bulk materials during transport which can be prevented with a tarp system, which is a very popular dump option. If the dump body will be utilized for applications such as road construction or working near heavy traffic, amber strobe or beacon lights are recommended to increase visibility and safety. A metering chute installed in the tailgate enable users to easily transfer bulk materials from the dump body to a wheelbarrow, especially common in the landscaping industry.

“Regardless of how your next dump body is configured, safety should be the number one concern for all operators,” stresses Sunila. “I tell operators there are two things they should never do with a dump body: place themselves under the body when it is raised (to perform service or maintenance) without the body prop engaged or stand behind/close to the tailgate during dumping. At the end of the day safety is the most important thing on the jobsite.”