Publish Date

May 9, 2023

Social Share

What is Preventative Maintenance?

Preventative maintenance is the act of maintaining a system to ward off future issues. Essentially, you’re trying to stop problems from happening.

In terms of vehicles, “preventative maintenance ensures the equipment on your unit is ready to work,” Craig Baker, Knapheide Field Service Engineer, said. “It will help ensure your product lasts a long time, helps prevent unexpected downtime and saves you money in the long run. Every manual that comes with the truck will have a preventive maintenance recommendation, and if followed, will help ensure you have a long, trouble-free run time.”

Why Do Preventative Maintenance in the Spring?

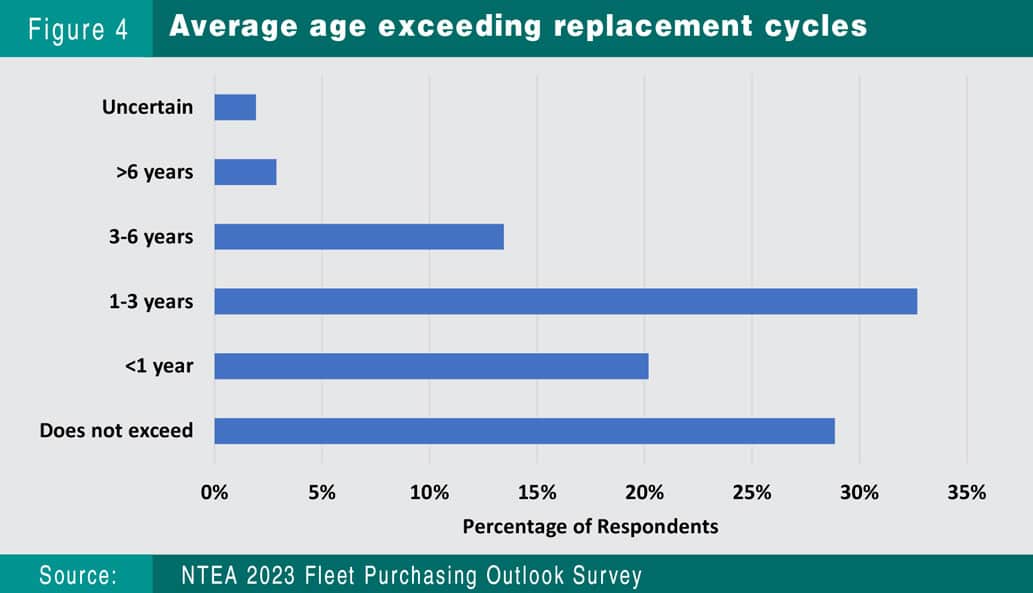

Although winter is over, the effects of the season may still be lingering. In the winter, many vehicles are exposed to cold temps, potholes and salt, all of which take a toll on the vehicles and their systems. Because supply issues are driving many fleet owners to extend the lives of their vehicles and exceed normal replacement cycles, it remains incredibly important that you take care of your fleet by prioritizing regular preventative maintenance.

Did you know…

According to the 2023 Fleet Purchasing Outlook report published by NTEA, “[o]ver 69% of respondents reported their average commercial vehicle ages are exceeding normal replacement cycles” (n.d.).

For a little more than 20% of the respondents, the average exceeded was less than one year, but for more than 32%, the average over was actually one to three years! Around 16% were even longer, exceeding three years!

How To Keep Your Vehicle Running Optimally

We spoke with Tim Pike, General Manager of Knapheide Truck Equipment Centers Texas, for guidance on what maintenance is essential for fleet and truck owners. Below is a handy checklist for keeping your fleet vehicles in tip-top shape.

Spring Maintenance Checklist:

Change hydraulic fluids, oils and filters on all equipment while also inspecting hoses, clamps and fittings for any sign of wear, weathering or damage

Cycle/test equipment

Conduct a visual inspection of torque marks on all critical fasteners and body-mounting hardware (torque testing may be required on some hardware per OEM recommendation)

Visually inspect the underside of the body for any damage, excessive dirt or debris buildup

Perform proper lube maintenance for all moving parts to prevent fatigue

Inspect all body wiring and lighting to ensure operational compliance with state laws

Visually inspect trailer wiring and all hitch-mounting hardware

Inspect, test and lube all door handles, locks and hinges (tailgate and exterior body doors, too, if applicable)

Replace disposable batteries in wireless equipment

Replace worn or damaged maintenance or safety warning decals

For mobile crane truck applications: Annual crane inspections (not just for proper maintenance requirements, but also safety and OSHA compliance)

What’s Next?

Whether completed in-house or outsourced, keep a record of all the maintenance performed on each vehicle and by whom. Documentation might be handy for those servicing your vehicle come fall.

Looking ahead, consider completing your maintenance during October, which is Fall Car Care Month, before winter hits.