Publish Date

September 8, 2021

Social Share

“It is a good feeling when you pull onto a jobsite and a group of people have to come check out our service trucks.”

Founded in 1956, the Franklin Township Sewerage Authority in Somerset County, New Jersey serves a population of over 65,000 residents across 46 square miles.

“We service about 200 miles of sewer lines and 23 pump stations,” says Steve Holzinger, who serves as a maintenance technician for FTSA. “We have seven people in our front office staff and 14 people in the field operations staff. We have a very proactive preventable maintenance program that helps our system run smoothly.”

The amount of maintenance and repairs carried out by FTSA requires organization, efficiency, and practical work trucks that can withstand a lot of heavy duty work.

“Previously, we would use whatever truck body and chassis was in the state contract,” informs Operations Manager Scott Nocero. “Since I started ordering operational equipment, I prefer to spec what fits our needs versus what is in a contract. I generally have an initial vision, then we take added comments from our maintenance staff and come up with a spec.”

A trip to Knapheide’s headquarters in Quincy, Illinois allowed FTSA to gain a better understanding of the options available in the market and to see how Knapheide can tailor bodies to the specific needs of each customer.

“We toured [the Knapheide] facility in September of 2019,” recalls Holzinger of his first introduction to the company and its products. “I really enjoyed getting to see the bodies built from start to finish and really appreciated the attention to detail taken at every step of the assembly process.”

After that visit, they say the decision was easy.

FTSA chose Knapheide after seeing the quality and attention to detail in the manufacturing process.

To stand up to the demands of the job, FTSA chose Knapheide truck bodies.

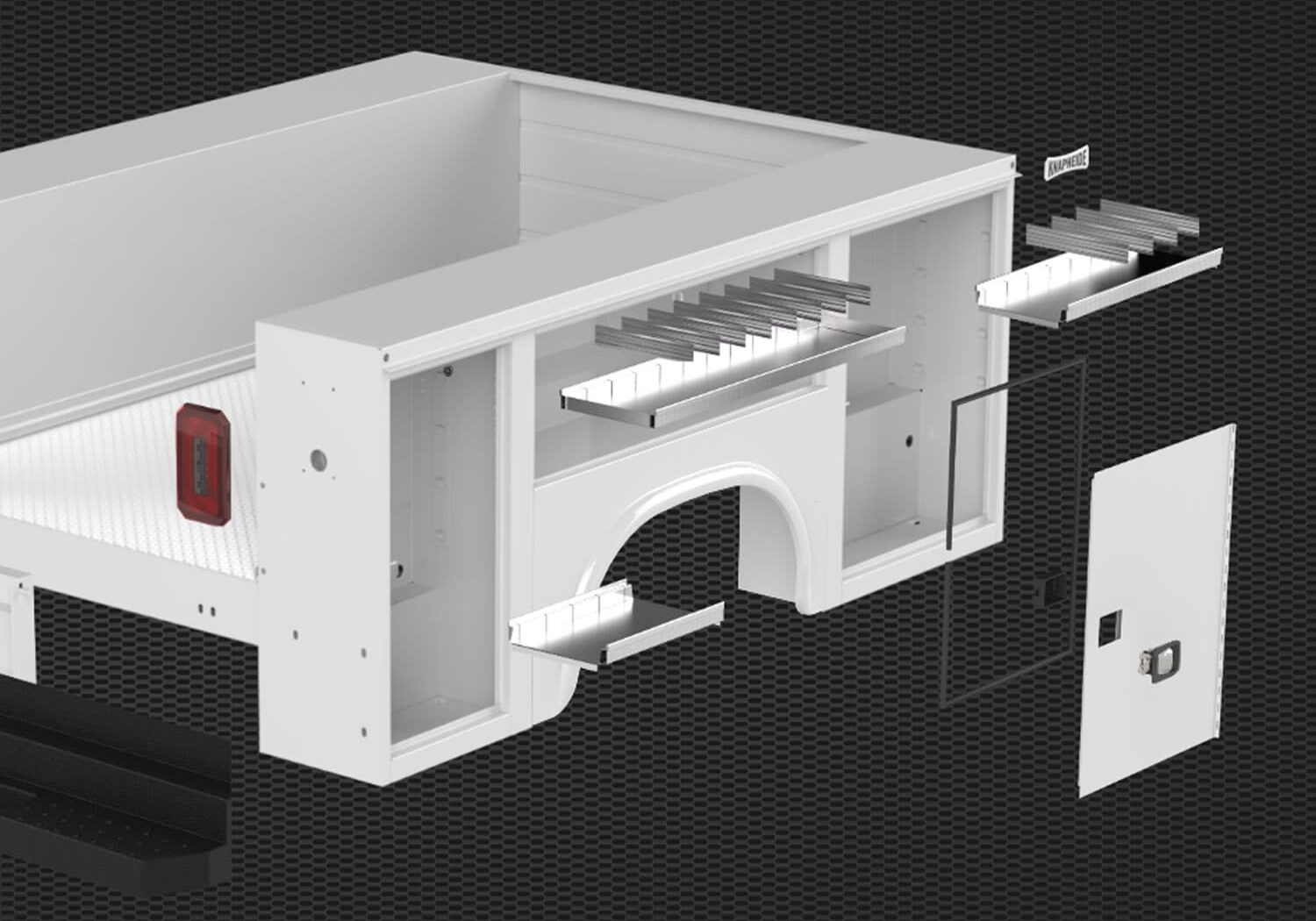

The department took delivery of their first Knapheide body, a KMT, in February 2020. The unit features an 11-foot Service Body upfitted on a Kenworth chassis and accompanied by a Stellar crane. After a few months of positive experiences with the KMT, the decision was quickly made to add another Knapheide body to their work truck lineup, a Ram 3500 received in the summer of 2020.

Of the two trucks currently in use by FTSA, the KMT is a standard unit. But, when the time came to add the second Service Body to their lineup, they chose to spec some more custom options to better meet their needs.

“Again, I’m very particular and conscientious about our specific needs,” says Nocero. “We have specific preferences in regard to the layout of our tool storage, lighting, and other elements of our trucks.”

Their requirements were met thanks to Knapheide’s dedication to providing customers with ideal upfit solutions no matter their line of work.

“We customized the cabinets and the tool box placement to fit our needs,” Holzinger says of the customization. “We also added some custom strobes and work lights on extendable poles, a 3000-watt inverter with GFCI outlets in the back of the truck, and a rotary compressor plumbed to the rear of the truck.”

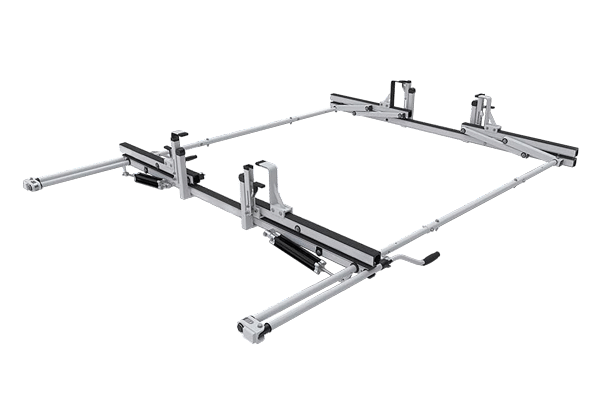

Additionally, an E-Track system to secure tools and accessories with greater ease, custom slide-out steps to better access the top of the toolboxes, and a welder/generator for fabricating in the field and higher-demand power usage were added to the build.

FTSA utilizes every square inch of their truck bodies and their components, fully stocking all the tools needed to successfully accomplish the multitude of various installation, maintenance, and repairs their day-to-day schedules require. The versatility of their trucks allows them to be consistently flexible.

The team carries everything needed to pull and repair pumps, valves, and generators across their 23 pump stations. The crane truck gives them the ability to fabricate anything needed in the field for emergency repairs or everyday work. They’re also able to easily haul submersible pumps of any size and pick up new equipment to be installed.

“Our days stay pretty busy and can go from one extreme to another,” says Holzinger. “We can go from painting piping in a pump station to pulling a jammed pump with our crane truck or welding broken aluminum railing at a station. Through it all, no matter what, our Knapheide bodies are there for everything we do and make sure our tools stay clean and in order.”

Customization of their truck bodies has allowed FTSA to remain more organized and efficient on a daily basis.

FTSA’s experience with Knapheide has been overwhelmingly positive.

According to Nocero and Holzinger, every crew member that uses their trucks leaves with a positive impression.

“The crew that uses these trucks on a daily basis are extremely pleased,” Holzinger says. “You don’t mind going on a service call late at night when you know you have everything in place in your truck and you can open a cabinet and have the lighting to see what you need.”

Nocero says that, as a manager, it’s important for the staff to have the proper equipment to perform their jobs safely and efficiently, which includes having accessibility to their tools and other equipment while responding to both routine and emergency maintenance. And that’s just one of the many reasons they chose Knapheide bodies for their operations.

“We just haven’t had the same experience with other truck bodies,” Nocero says. “We had much higher expectations of their longevity that simply weren’t met.”

Holzinger offers some additional insight into the impression Knapheide has left.

“In my time at FTSA, we have tried a few different truck bodies for our service trucks,” Holzinger offers. “Knapheide is the first brand we went back to for a second body. Other bodies are mass produced to turn out production. Knapheide takes the time to make sure their bodies fit the needs of the customer. With the price of things today, you need to make sure you get what you are paying for. Knapheide will get everything to the jobsite day to day and you know they will stand behind their product. We always make sure to tell others about Knapheide and their high quality products.”